Orthofix Announces Its First 3D-Printed Titanium Cervical Spacer System with Nanovate Technology

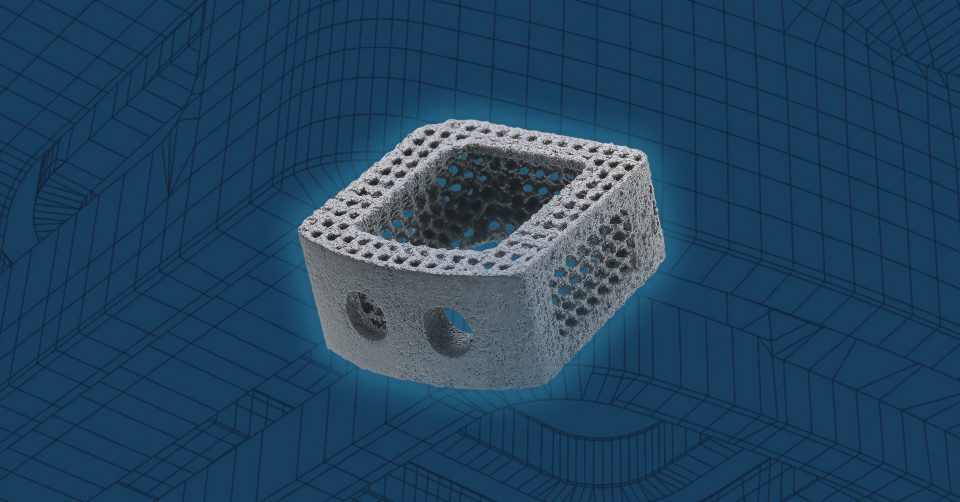

Designed with nanoscale surface features, the CONSTRUX Mini Ti System is Orthofix’s first 3D-printed titanium (Ti) interbody introduced to the market.

LEWISVILLE, Texas–(BUSINESS WIRE)–Orthofix Medical Inc. (NASDAQ:OFIX), a global medical device company with a spine and extremities focus, today announced the U.S. Food and Drug Administration (FDA) 510(k) clearance and the first patient implant of the 3D-printed CONSTRUX™ Mini Ti Spacer System. Developed to enhance anterior cervical discectomy and fusion (ACDF) procedures, the CONSTRUX Mini Ti cervical spacer with Nanovate™ Technology is the first 3D-printed titanium interbody introduced to the market by Orthofix.

“The ACDF procedure, which is often used to treat a herniated cervical disc or degenerative disc disease, involves replacing a patient’s damaged cervical disc with an interbody packed with a biologic to promote fusion in order to provide stability and strength to the area,” said Wayne Cheng, M.D., an orthopedic spine surgeon operating at Loma Linda University Medical Center in Loma Linda, CA, who performed the first patient implant procedure. “The CONSTRUX Mini Ti System’s optimized porosity and surface allows bone to grow into and through the spacer in order to aid with the patient’s fusion.”

The CONSTRUX Mini Ti Spacer System with Nanovate Technology is one of many Orthofix products with nanotechnology FDA clearance including the CONSTRUX™ Mini PTC Spacer System, the Pillar™ SA PTC Spacer System, and the FORZA™ PTC Spacer System. When compared to solid PEEK devices, the 3D-printed endplates of these implants with Nanovate Technology show a significant increase in growth factors involved in osteogenesis and osteoblast maturation resulting in a more favorable osteogenic environment for bone ingrowth.

“Orthofix’s cervical spine offerings feature a wide array of implants ranging from motion-preserving products like the M6-C™ Artificial Cervical Disc to advanced interbody and fixation solutions that aid surgeons in restoring spinal alignment and decreasing pain and nerve compression,” said Orthofix President of Global Spine Kevin Kenny. “We are dedicated to expanding our comprehensive cervical spine solutions with technologies like the CONSTRUX Mini Ti Spacer System that can make a meaningful difference in our product offerings and in the lives of patients.”

The CONSTRUX Mini Ti Spacer System features include:

- 3D-printed porous titanium with macro, micro, and nanoscale surface features

- Nanoscale surface that has been shown to increase proliferation and alkaline phosphatase activity (an early osteogenic differentiation marker) in human stem cells in vitro*

- Endplates with 400 micron pores and 50-percent porosity designed to help facilitate bone ingrowth**

- Functional gradient porous structure with 80-percent porosity at the midline of the implant which allows for increased fluoroscopic visualization

- Large center opening with concaved inner walls for packing bone-grafting material

- Straightforward instrumentation for easy implantation

Orthofix offers a comprehensive cervical portfolio with differentiated technologies across biologics, bone growth therapies and spinal implants. Learn more about our cervical solutions by visiting Orthofix.com.

*As suggested in an in vivo ovine lumbar spinal fusion model

**In vitro performance may not be representative of clinical performance