Orthofix Announces the Full Commercial Launch of WaveForm A 3D Printed Anterior Lumbar Interbody

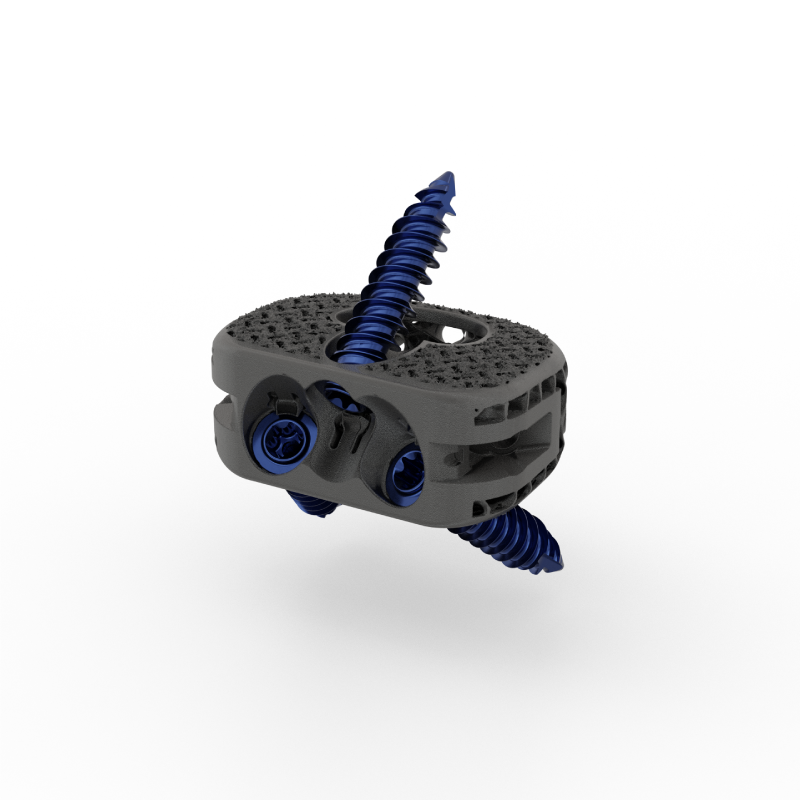

LEWISVILLE, Texas–(BUSINESS WIRE)– Orthofix Medical Inc. (NASDAQ:OFIX), a leading global spine and orthopedics company, today announced the full commercial launch of the WaveForm® A interbody for Anterior Lumbar Interbody Fusion (ALIF) procedures. The WaveForm A interbody seamlessly integrates with the company’s Meridian ALIF system for treating patients in need of fusion due to degenerative disc disease. The proprietary wave-like design of the WaveForm A interbody provides a balance of strength, porosity and stability, with a large implant graft aperture for bone graft material to aid in creating an osteoinductive environment to optimize supplemental fixation procedures.

“Implant design and surface technology play a vital role in the bone growth process during fusion,” said Dr. Neil Arif Tayyab, orthopaedic spine surgeon at Girard Orthopaedic Surgeons, in San Diego, CA. “Newer designs such as the WaveForm A interbody can help stimulate a better bone growth response and give me greater confidence that the patient will have a successful fusion.”

The Meridian ALIF system is a modular instrument and implant system designed to help streamline ALIF procedures by providing diverse fixation options for single and multilevel ALIFs in a reduced number of trays. Meridian is compatible with both the WaveForm A interbody and the company’s Reef™ A interbody featuring its proprietary NanoMetalene® surface technology and Reef Topography™. With the launch of WaveForm A, the Meridian system can more completely address the approximately $200 million dollar ALIF market segment in the U.S.1

The 3D printed WaveForm A implants feature WaveForm® technology, a repeating and continuous wave-like structure. WaveForm was created to withstand high compressive loads while delivering an endplate porosity that maximizes the potential for early stabilization2,3. This balance of strength to porosity offers increased opportunity for bone packing, decreased stiffness profile and enhanced imaging properties.3

“Our Meridian ALIF system integrates the most advanced technologies into our surgical sets, minimizing the need for multiple instrument sets during the procedure,” said Kevin Kenny, President of Global Spine. “The WaveForm A interbody is an exciting addition to our portfolio of solutions for ALIF procedures and enables us to provide a more streamlined option so surgeons can do more for their patients.”

Advancing Care with ALIF

The ALIF market can be segmented by material into non-3D printed metal, PEEK (standard and titanium-based advanced surface technologies), 3D printed metal, and machined bone markets. It is estimated that more than half of the U.S. ALIF interbody market today is addressed by PEEK devices. Due to their clinical advantages, 3D printed and advanced surface technologies-based interbody devices are expected to grow faster than the overall interbody market in upcoming years as they take market share from PEEK devices, ultimately leading to a larger market share than standard PEEK.4

The WaveForm A interbody and the Meridian ALIF system are available in the U.S. Learn more about the Company’s interbody systems here.

1Market research on file. Based off iData Research Inc. 2021 numbers.

2Kelly, Cambre N., et al. “Design and structure–function characterization of 3D printed synthetic porous biomaterials for tissue engineering.” Advanced healthcare materials 7.7 (2018): 1701095.

3O. Al-Ketan, R. Rowshan, R.K. Abu Al-Rub, Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials, Addit. Manuf. 19 (2018) 167-183.

4Data on file.